Sourcethe finest Raw Material

Raw Material Egyptian Sand is one of the purest source for slica, with queries only 100 km away….

Recycled Glass Only Premium flint cullet is used, well sorted from debris and metals , well cleaned.

We melt glass using advanced equipment supplied by the industry leader “SORG”, using less energy…

Total melting capacity: 420 TPD

Dozing Glass gobs:

The “Emhart” feeders offer the ability to improve the thermal homogeneity and minimize weight variations.

High productivityglass forming machinery

After Melting, Kandil Glass is running the latest technology in forming machines from Emhart.

Furnace 1 (60 tons/day)

Furnace 2 (350 tons/day)

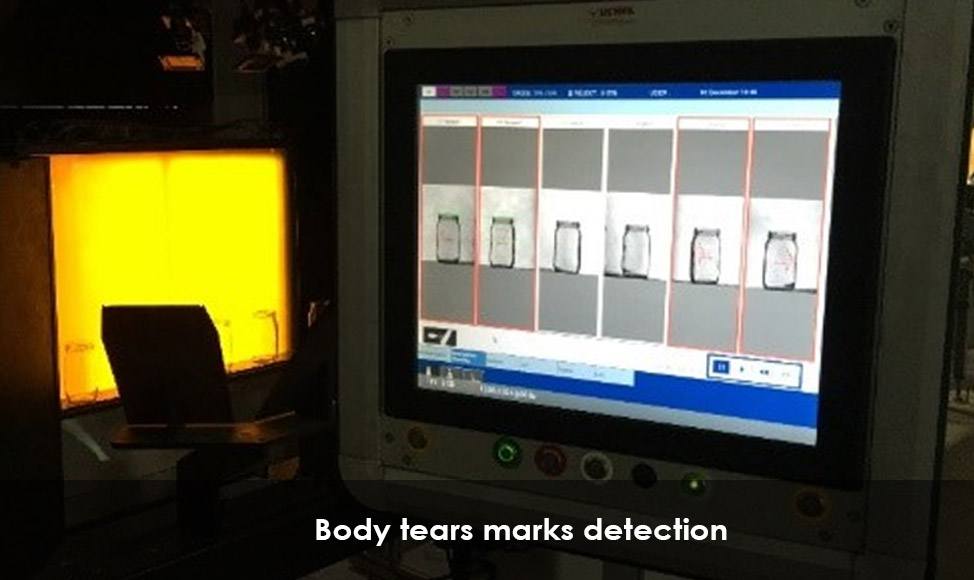

Control the quality

Finish Inspection Guarantee the quality of our products with imaging technology We installed the latest “IMAGING” technology, just released on the market to ensure the quality of our products Cyclops Multiview™ is a new technology that inspects the sealing surface of glass containers by using ultra-definition cameras with multi colors imaging technology. Volcano® SW combines programmable lighting and high-resolution color cameras to inspect the most complex containers.

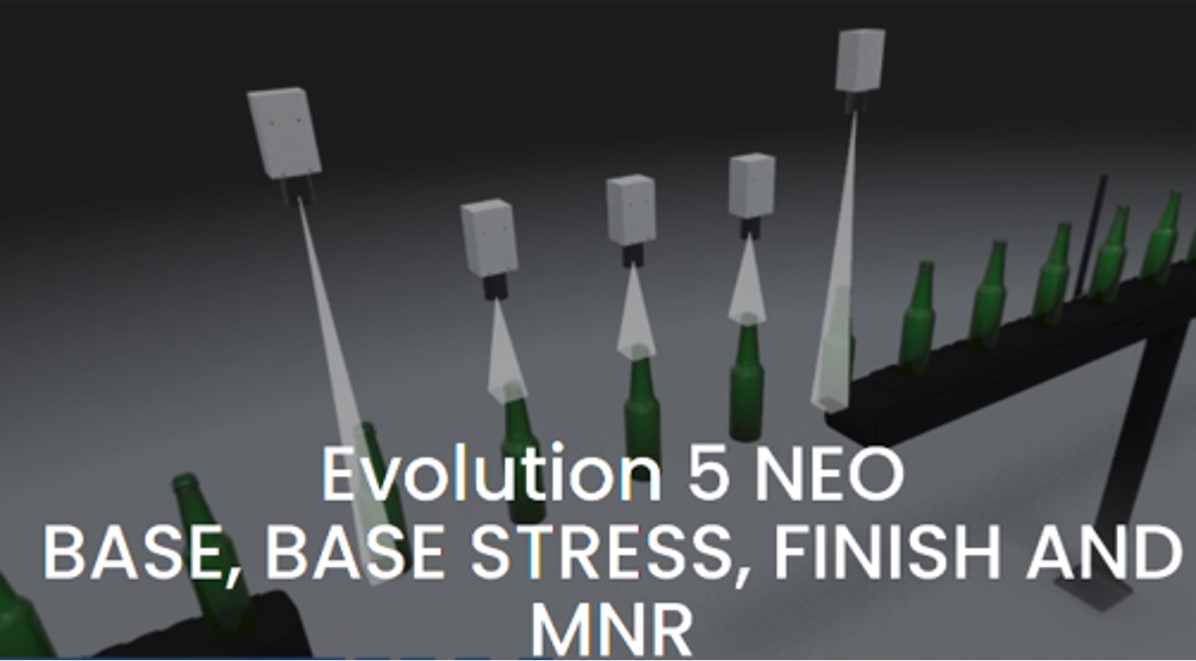

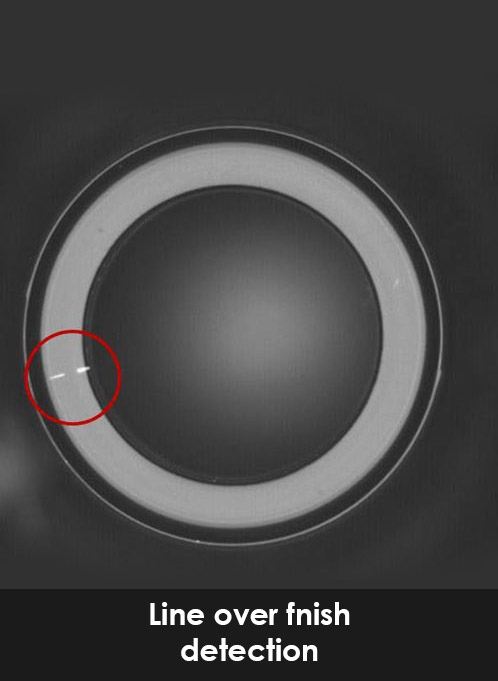

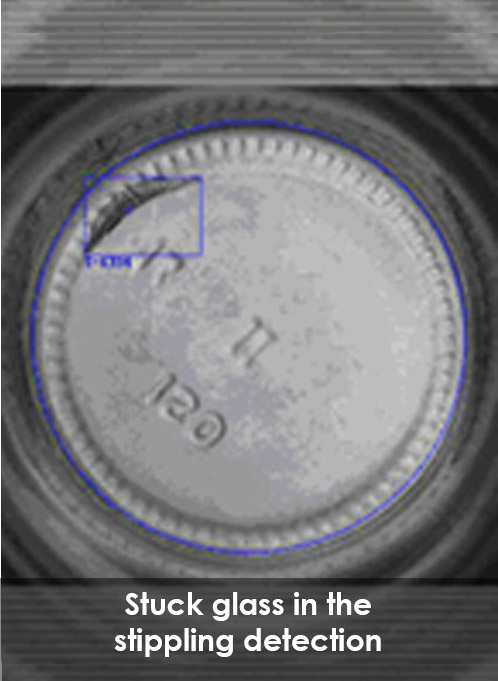

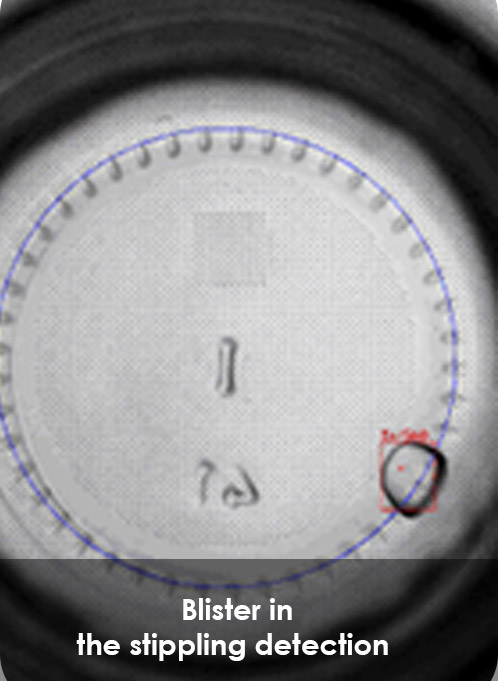

Base Inspection

EVOLUTION 5 NEO is a fully automated machine for the base, finish, base stress inspection, and mold number reading.

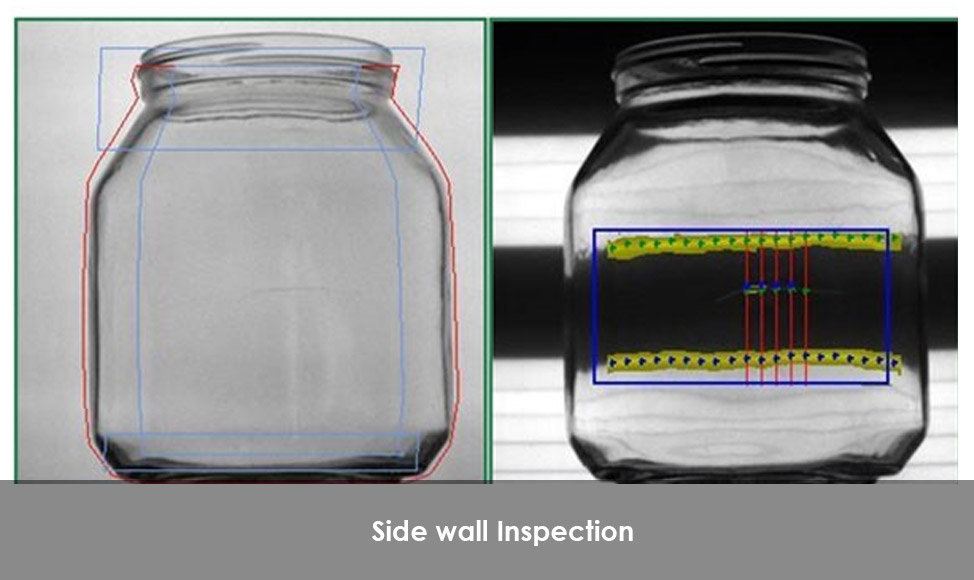

Side Wall Inspection

12 high-definition cameras that provide full-body coverage, and reject the defective units in case there is any difference in colors.

Packaging

Products are packed in industrial packaging made from recycled materials. Once a pallet of bottles, packs, or cases is complete, it is fully encased in a plastic wrapper which protects Kandil products during delivery and storage.